Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

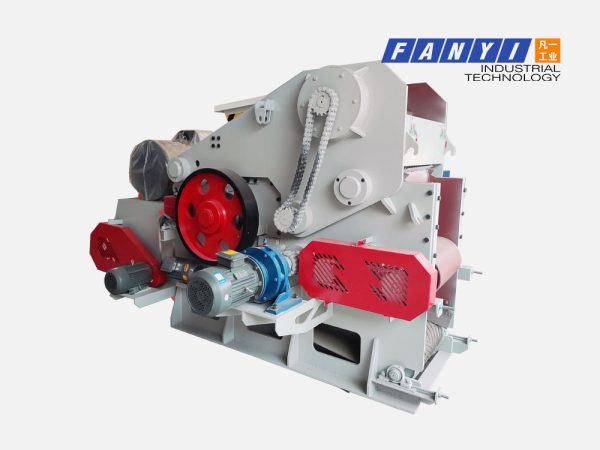

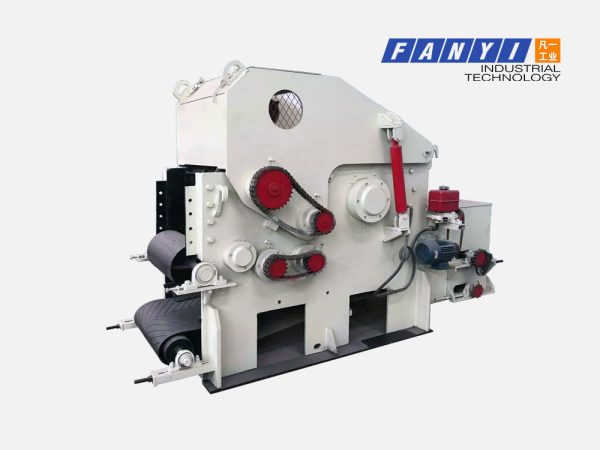

Wood chipper/wood chipper shredder is mainly used to crush big wood logs or wood timber,plywood,wood branches,furniture waste into small chips,the thickness of last chips is 3mm-5mm,length and width is about 15-30mm,it is wood chips not wood shavings.By adjusting knives gap,outlet chips dimension will be adjusted.

Raw material to process: Wood logs, tree branches and limbs, veneer, stump, pulp wood, waste wood, cores, slabs, etc.

Capactiry: 10 – 15 tons/h

BRIEF INTRODUCTION OF DRUM CHIPPER

Drum chipper is a special equipment for producing wood chips. It can work with all kinds of wood materials such as wood logs, tree branches, wood slab, twigs, planks, bamboo, veneer, tree stump, waste wood, etc.

Drum chipper is widely used in Wood chips mill, MDF board factory, Biomass power plant, Paper pulp plant and Wood pellet factory. It is a important equipment to prepare perfect wood chips of different size for those plants or factories.

| Detailed specification of Drum Chipper BX216 | |||

| 1 | Basic type | Stationary | √ |

| Towable | Optional | ||

| 2 | Driving type | Electric motor | √ |

| Diesel engine | Optional | ||

| 3 | Feeding type | Manually | |

| By belt conveyor | √ | ||

| 4 | Discharge type | Blow out | |

| By belt conveyor | √ | ||

| 5 | Control type | Control box | √ |

| Remote control | Optional | ||

| 6 | Power | Main motor power | 55kw |

| Assistant motor power | 12.9kw | ||

| 7 | Fly knife qty. | 2 – 4 pcs (Depend on the wood chips size) | |

| 8 | Feeding open size | 550 x 260mm | |

| 9 | Capacity | 10 – 15 tons/h | |

| 10 | Wood chips size | Ordinary 25-35mm. Other size is customized. | |

| 11 | Main machine dimension | 2850x2000x1500mm | |

| 12 | Total weight | 4680kg | |

Drum chipper is composed of feeding system, chipping system, outlet system and control system. The raw materials will become final needed wood chips as the following steps:

Feeding conveyor—Force feed roller—Chipping—Outlet conveyor

1.Force feed roller have large amount of teeth around the roller. The raw materials will be forcefully pushed into the chipping system.

2.Chipping system consist of knife drum, bed knife assembly and sieve mesh. There are different quantity of knives ( 2-12 pcs ) installed on the drum for making different size of wood chips. The length of the wood chips is customized accordance with the requirement of different industries.

Structure of drum chipper

1. The main body of our drum chipper is welding structure with high strength steel plate. Thickness of steel plate is from 25mm to 50mm for different model. The strong structure and the strict welding control ensure the chippers run steadily and safely with very low noise and vibration.

2. The whole process of chipper’s assembling is under strict supervision. All assembly process must comply with the technical standard. Our chipper are keeping much low failure rate and working for long life because of the meticulous assembly. We continuously improve the design and assembly of equipment details according to user feedback. Our chippers are becoming easier and easier to install, operate and maintain.

3. Drum chipper can make wood chips of different size by adopting different quantity of knives on drum. The quantity is from 2 pcs to 12 pcs. With different quantity of knives, the wood chips length are standard designed from 10mm to 50mm. In a reasonable scope, other size of chips could be customized as user’s requirement. We adopt different hardness of wood chipper knife to work with different kinds of woods. With special design and reliable knives layout, our drum chipper works more efficiently.

4. There are several types of feed conveyor for choice. Rubber belt conveyor for light raw materials such as tree branches and small logs. For heave wood materials, steel chain plate conveyor is a better solution. It is of much strong and have much longer running life. For loose materials, vibrating conveyor is the best choice.

5. All the running section of the wood chipper is controlled by one combined control panel. It is equipped with infeed, outfeed, feed reverse, oil pump and emergency stop control buttons. All the control panel have motor protection function.

For security, there is remote controlling for choice. It is a effective solution to protect the wood chipper operators.

| Model | BX215 | BX216 | BX217 | BX218 | BX2110 | BX2113 | BX2113C | BX2116 | BX2116D |

| Knife drum diameter (mm) | 500 | 650 | 650 | 800 | 1000 | 1300 | 1300 | 1600 | 1600 |

| Feed open size (mm) | 400×200 | 550×260 | 700×260 | 700×330 | 1000×400 | 700×520 | 1250×520 | 900×680 | 1250×680 |

| Knife drum rotating speed (rpm) | 620 | 590 | 590 | 580 | 530 | 500 | 500 | 460 | 450 |

| Knife quantity (pcs) | 2-4 | 2-6 | 2-6 | 2-6 | 2-8 | 2-8 | 2-8 | 2-10 | 2-10 |

| Capacity (m³/h) | 5-8 | 10-15 | 15-20 | 18-25 | 30-40 | 30-40 | 50-70 | 90-110 | 160-190 |

| Main motor power (kw) | 45 | 55 | 75 | 110 | 160 | 220 | 400 | 560 | 710 |

| Wood chips size (mm) | 10-30 | 10-35 | 10-35 | 15-40 | 15-40 | 15-40 | 15-40 | 15-40 | 15-40 |

* The specifications are approximate and will vary depending on options selected.

1. After selling, we provide the warranty of one year.

2. Our professional service includes: free training, guidance, installation, commissioning.

3. We devote to all-round service of all products from production to maintenance.

4. If you have any problems, we will try our best to help at the first time.

After 30 years of unremitting efforts and development, we have delivered more than 30,000 sets of machines to all over the world.

We have kind customers from more than 100 countries in Asia, Europe, Africa, Latin America, etc.

You must be logged in to post a review.

Reviews

There are no reviews yet.