Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

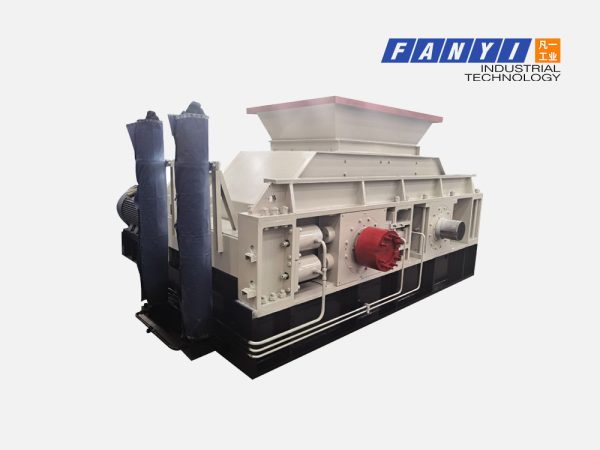

The roll crusher is suitable for coarse and medium crushing crisp and massive materials in the cement, chemistry, power station, mines, metallurgy, building materials, refractory and coal mines and other industries.

Capacity: 2-140 T/H

Fedding size: ≤150mm

Discharge size: ≤2-50m

Crushing Material: River pebble, granite, basalt, iron ore, limestone, quartz, gangue and so on.

What’s the double roller crusher

The Doule Roller Crusher, also known as roll crusher, toothed roll crusher, is suitable for fine crush the medium hardness rock with compressive strength ≤160MPa, such as ore, rock, coke, coal, clinker, ceramic raw materials, slag, refractory materials, and chemical materials.

According to the number of rolls, the roll crushers can be divided into single roll crusher, double roll crusher or, four roll crusher. Double roll crusher is the most used type. We produce industrial roller crushers and laboratory uses small roll crusher.

Advantages

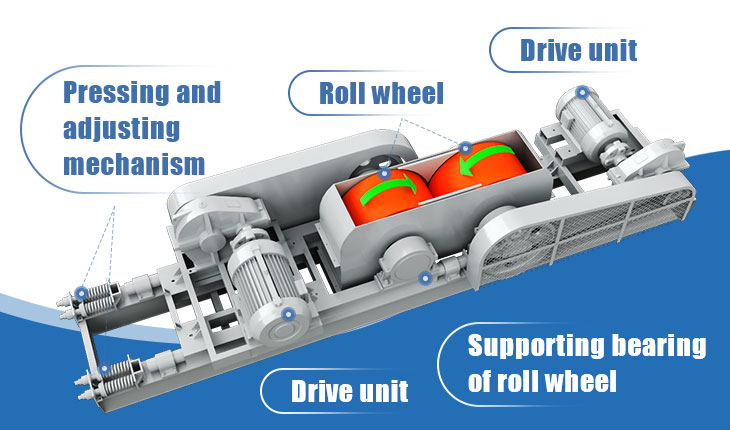

Main parts:Bearing box, roll shell, bearing housing, adjusting rod, motor, carrier, fixed roller, movable roller and safety spring, etc.

Working Principle of Double Roller Crusher: The roller of the roller crusher is supported by the spring pressure. Under normal working conditions, the spring force is sufficient to overcome the crushing force of the crushed material. By changing the number of spacers between the frame and the movable bearing, the width of the discharge port between the two rolls can be adjusted to adjust the grain size.

When there is a material that cannot be broken into the crushing chamber, the spring is compressed, and the movable roller is retracted to increase the discharge opening. After the material is discharged, the movable roller is reset under the spring pressure.

Operation: The main wearing part of the roller crusher is the crushing roller. Precautions as follows:

Iron removal before crushing; prevent sticky mud clogging; pre-pick out the large ore rock; good lubrication condition.

| Model | Input size | Output size | Capacity | Power |

| (mm) | (mm) | (T/h) | (KW) | |

| 2PG0404 | 120 | 10-50 | 6-40 | 4×2 |

| 2PG0605 | 200 | 10-70 | 10-80 | 11×2 |

| 2PG0806 | 300 | 10-90 | 20-150 | 15×2 |

| 2PG1008 | 400 | 10-110 | 30-200 | 18.5×2 |

| 2PG0812 | 300 | 10-90 | 40-280 | 22×2 |

| 2PG1012 | 400 | 10-110 | 50-350 | 30×2 |

| 2PG1212 | 700 | 10-140 | 65-450 | 37×2 |

| 2PG1612 | 1000 | 10-180 | 80-600 | 75×2 |

| 2PG1618 | 1000 | 10-200 | 90-780 | 90×2 |

You must be logged in to post a review.

Reviews

There are no reviews yet.