Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

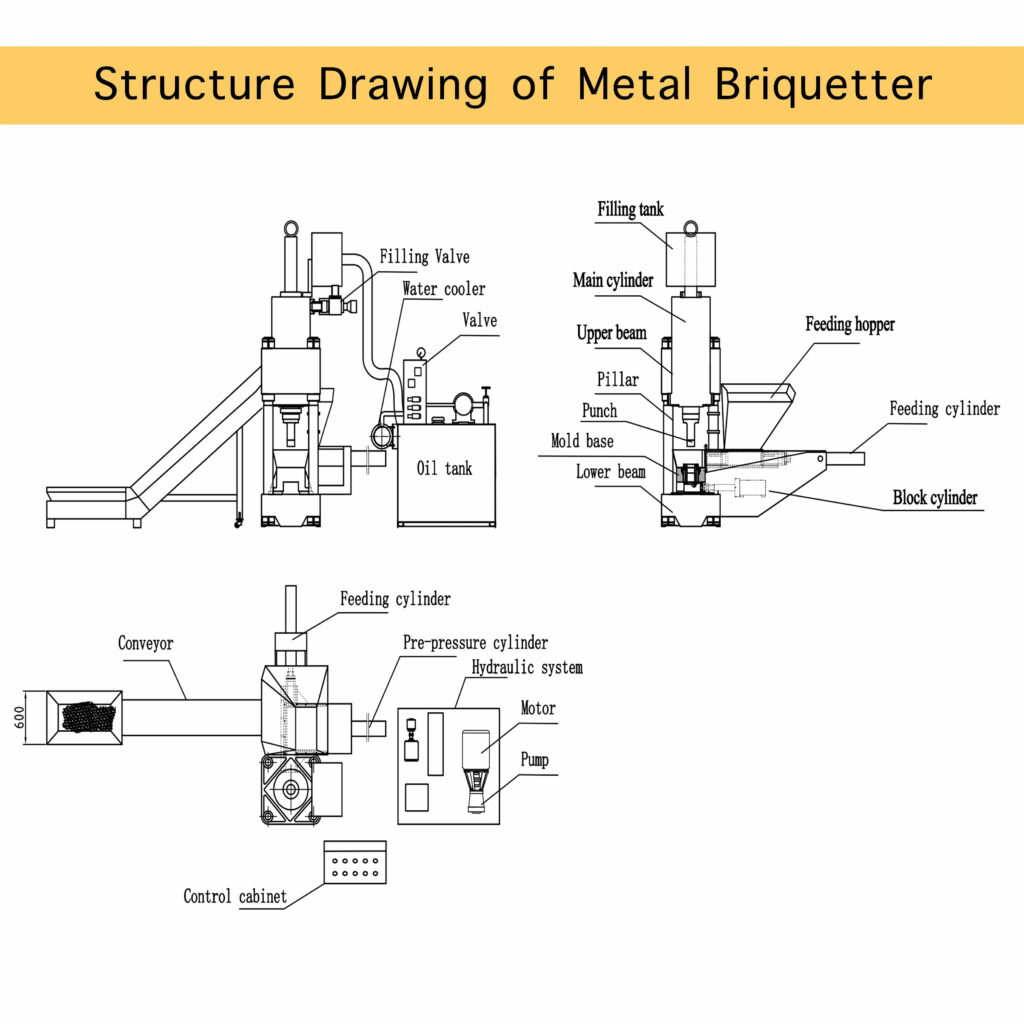

Hydraulic scrap metal chip briquetting press machine has good benefits for metal recycling industry. Nowadays, the shortage of available resources is a problem that every country is facing. No matter developing or developed countries, how to do best recycle is always a hot topic. So we design vertical type or horizontal type hydraulic scrap metal chip briquetting press machine for our clients to deal with their scrap metal to meet our clients’ requirements.

Hydraulic scrap metal chip briquetting press machine is mainly used for pressing all kinds of metal scrap (cast iron scrap, copper scrap, aluminum scrap, etc.) into blocks through the mold, which is convenient for the transportation and treatment of metal scrap. Hydraulic scrap metal chip briquetting press machine is the ideal equipment for copper and iron factory, non-ferrous metal

What is the Applications of this machine?

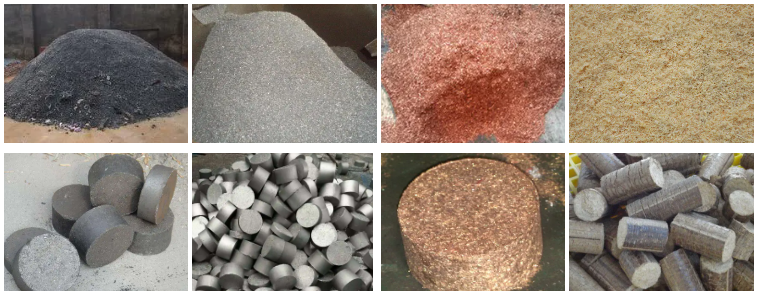

It is applied to compress metal sawdust(steel, cast iron,aluminum and copper) into density briquettes to reduce burning loss during smelting.Cast iron briquettes,can substitute pig iron as raw material.

Iron filings Aluminum scrap Copper shavings Sawdust

| Model | Cyl. Force | Press Mould | Pressure on Briquet |

Briquet Size | Briquet Weight – Cast Iron |

Production Rate – Cast Iron |

Motor |

| (kN) | (mm) | (MPa) | (mm) | (kg) | (kg/hr) | (kW) | |

| Y83-250 | 2000+550 | dia110×180 | 263 | dia110×(50-70) | 2.6-3.7 | 800-900 | 18.5 |

| dia120×180 | 221 | dia120×(50-70) | 2.9-4.1 | ||||

| YE83-250 | 2000+550 | dia110×300 | 263 | dia110×(70-100) | 3.6-5.2 | 1000-1100 | 22 |

| dia120×300 | 221 | dia120×(70-100) | 4.1-5.9 | ||||

| Y83-315 | 2850+550 | dia120×180 | 278 | dia120×(50-70) | 3.1-4.5 | 900-1100 | 22 |

| dia140×180 | 204 | dia140×(50-70) | 3.6-5.1 | ||||

| YE83-315 | 2850+550 | dia120×300 | 278 | dia120×(70-100) | 4.4-6.3 | 1100-1200 | 30 |

| Y83-400 | 3450+550 | dia125×300 | 326 | dia125×(70-100) | 5-7.2 | 1200-1300 | 30/37 |

| dia140×300 | 260 | dia140×(70-100) | 5.9-8.5 | ||||

| Y83-500 | 4900+600 | dia150×300 | 283 | dia150×(70-100) | 6.9-9.9 | 1300-1800 | 30/45 |

| dia180×300 | 196 | dia180×(70-100) | 8.9-12.8 | ||||

| YE83-500 | 4900+600 | dia150×300 | 283 | dia150×(70-100) | 6.9-9.9 | 1300-1800 | 45 |

| dia180×300 | 196 | dia180×(70-100) | 8.9-12.8 |

1.The technical parameters above are not binding,we reserve the right to adjust according to the actual need.

2.If you need non-standard models with different briquette size,different briquette shape,you can call us or email us for customization.

You must be logged in to post a review.

Reviews

There are no reviews yet.