Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

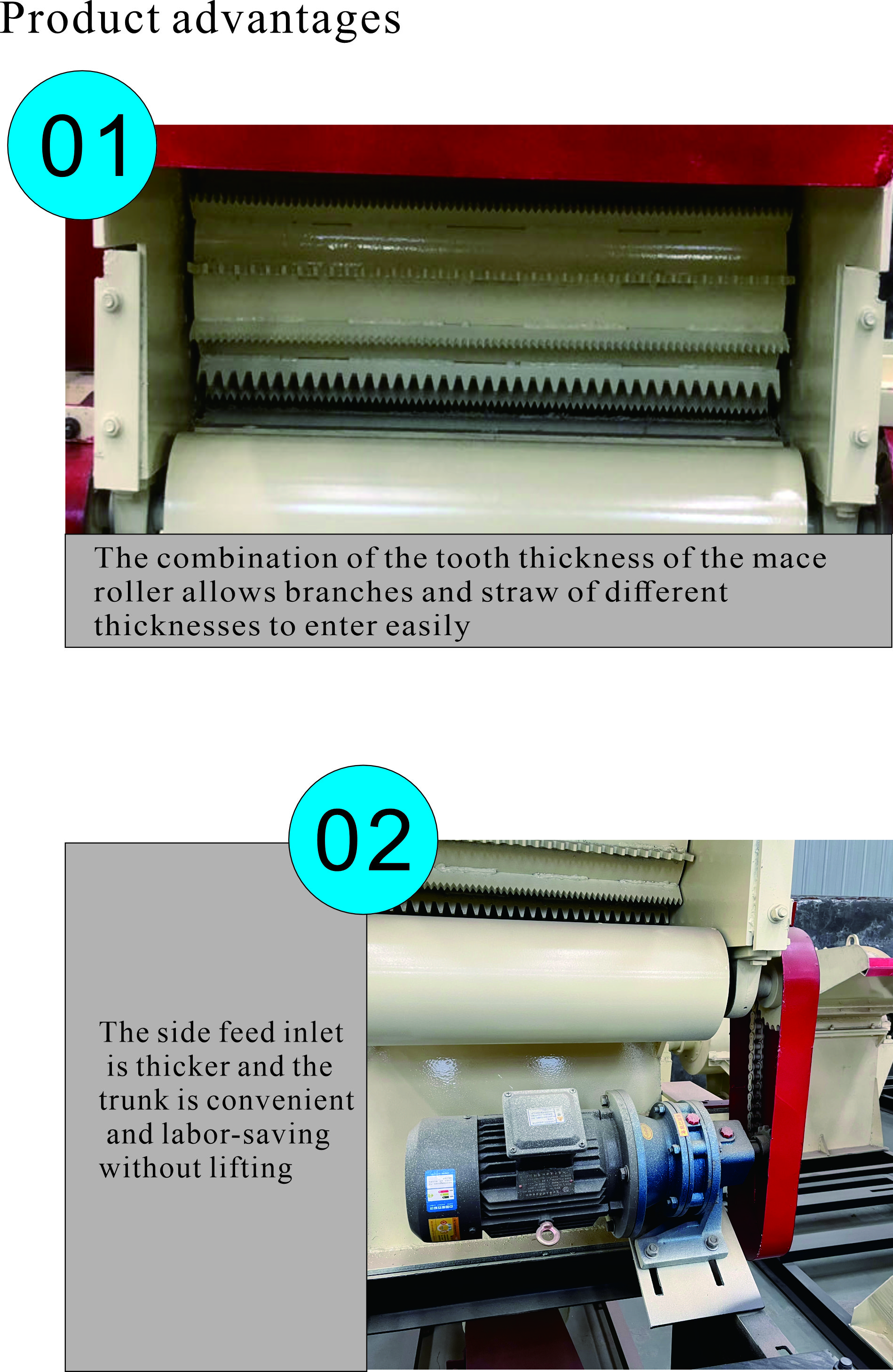

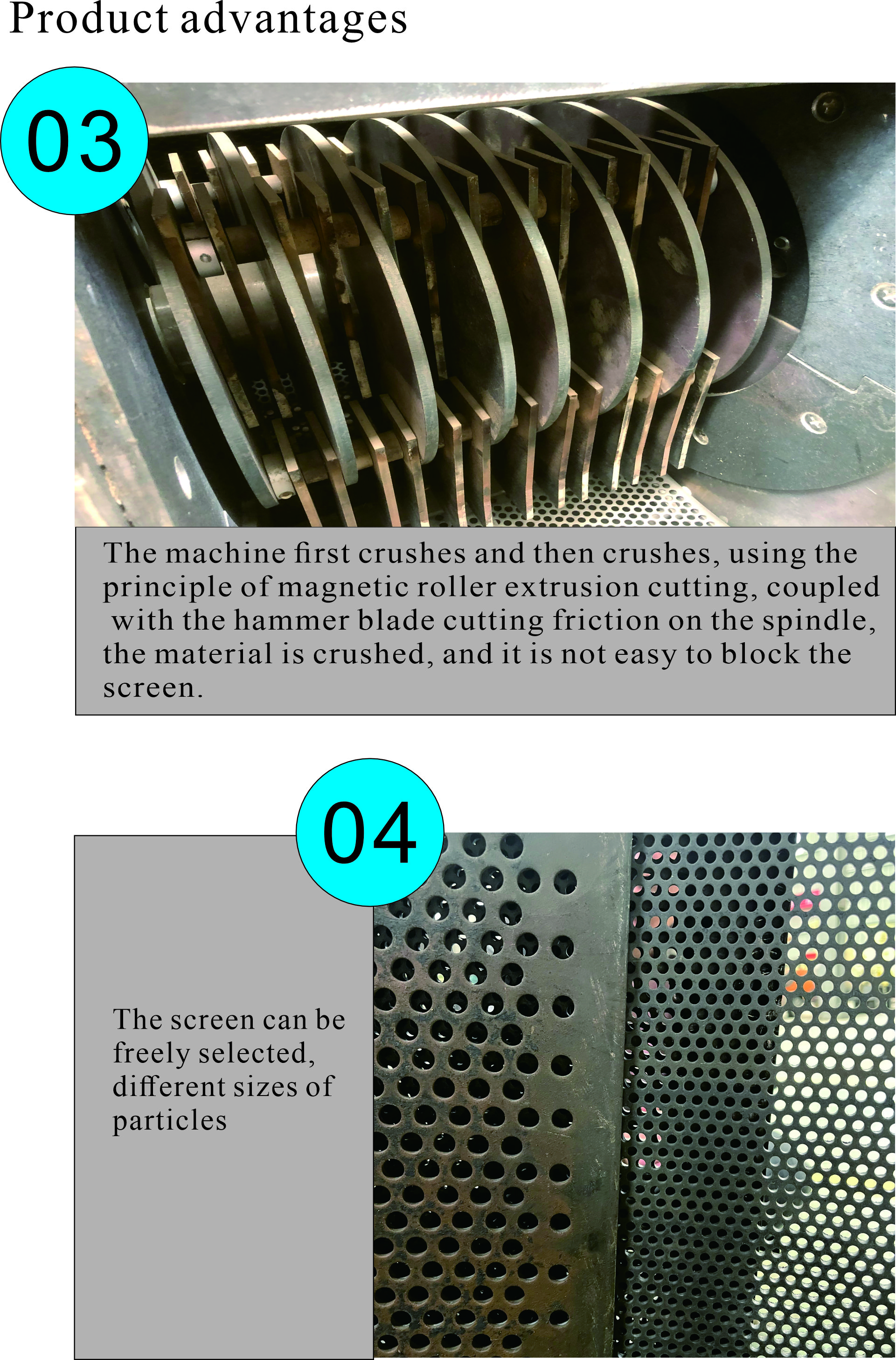

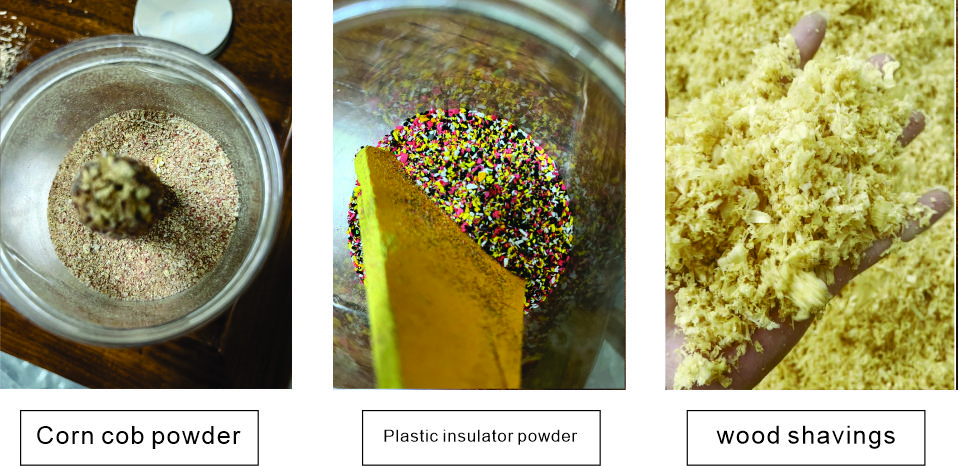

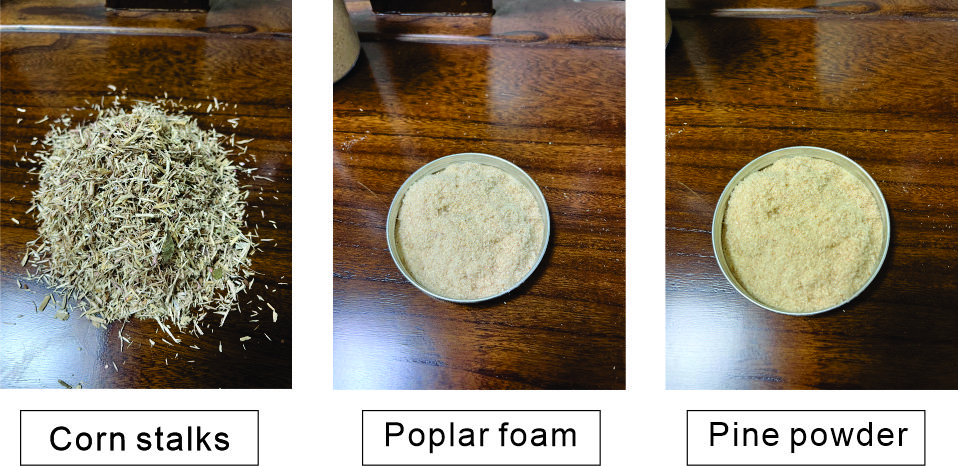

When the machine is working, the motor drives the rotating shaft to rotate, and the hammer on the rotating shaft will also rotate at high speed along with the rotating shaft. The wood material is sent into the crushing chamber from the feeding port and will be crushed soon under the impact of the high-speed rotating hammer. If the crushed material reaches the required fineness, it will be sent to the discharge port through the screen by airflow, otherwise, it will remain in the crushing chamber until it is crushed to the required size. For large-capacity hammer mill machines, we usually equip an independent fan to assist with the discharge of sawdust.

The wood pulverizer is composed of three parts: the body, the middle body and the lower body, and the middle body is equipped with a triple stator large circle, a crushing cutterhead and a fineness analyzer. The main machine adopts alloy cutting head. It has a high degree of wear resistance and thus also increases the output. With coarse crushing, fine crushing, and centrifugation to crush, the motor drives the pulverizer rotor to run at high speed, so that the machinery produces high-speed airflow to crush the material to produce high-strength impact force, compression force, cutting force, and achieve unique crushing function. Wood pulverizer is a new type of wood series production ideal woodworking machinery equipment. Wood pulverizer components are mainly composed of organic shell, bearing, screen, transmission wheel and trough frame. All materials are cast from manganese steel.

| Model | HMD800 | HMD1000 | HMD1200 |

| Capacity | 1.5-2t/h | 2.5-3t/h | 3.5-4t/h |

| Main motor power | 45kw | 75kw | 90kw |

| Force-feeding conveyor power | 1.5kw | 2.2kw | 3kw |

| Force-feeding conveyor length | 2 meters | 2 meters | 2 meter |

| Force-feeding roller power | 1.5kw | 2.2kw | 3kw |

| Force-feeding roller quantity | 1 set | 1 set | 1 set |

| Air fan motor power | 7.5kw | 11kw | 18.5kw |

| Air fan quantity | 1 set | 1 set | 1 set |

| Cyclone quantity | 1 set | 1 set | 1 set |

| Cyclone diameter | 800mm | 1000mm | 1200mm |

| Air lock motor power | 1.1kw | 1.5kw | 2.2kw |

| Air lock quantity | 1 set | 1 set | 1 set |

| Bag-type dust collector | 1 set | 1 set | 1 set |

| Dust collect bags quantity | 10 pcs | 14 pcs | 20 pcs |

| Rotor diameter | 750mm | 950mm | 1150mm |

| Cutting blades quantity | 4 pcs | 4 pcs | 6 pcs |

| Cutting blades length | 230mm | 300mm | 350mm |

| Hammers quantity | 48 pcs | 64 pcs | 76 pcs |

| Equipped sieve hole diameter | 6mm or 8mm or 10mm | 6mm or 8mm or 10mm | 6mm or 8mm or 10mm |

| Finished sawdust size | 4-5mm or 5-8mm or 8-10mm | 4-5mm or 5-8mm or 8-10mm | 4-5mm or 5-8mm or 8-10mm |

| Electric panel | 1 set | 1 set | 1set |

You must be logged in to post a review.

Reviews

There are no reviews yet.